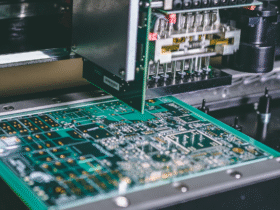

When it comes to high-tech robotics, precision and durability can’t be overlooked. Every component has to be securely held in place, often under extreme conditions, to ensure the robot performs as intended. This is where fasteners come into play.

Fasteners are essential hardware components that hold parts together, providing the stability and strength needed in all kinds of robotics assembly processes. From rivets and nuts to various right angle fasteners, each one ensures that a robot can function smoothly, withstand vibrations, and perform complicated tasks without failure.

In this article, we’ll talk about six types of fasteners commonly used in high-tech robotics assembly, each playing an important role in building advanced robotic systems.

1. Precision Screws for Detailed Assembly

Precision screws are essential in high-tech robotics assembly, especially for detailed tasks where accuracy is needed.

These screws are designed with exact dimensions and tight tolerances, ensuring that they fit perfectly into small, intricate parts of a robot. They’re made from durable materials and provide a strong hold while allowing for easy adjustments when necessary.

Precision screws are often used in areas where even the slightest misalignment could affect the robot’s performance. With their reliable grip, each component will stay securely in place, which makes them a key element in assembling advanced, finely-tuned robotic systems.

2. Threaded Inserts for Enhanced Joint Integrity

Threaded inserts help strengthen joints in complex robotics assembly processes. These inserts are placed into softer materials, like plastics or softer metals, to create a strong, durable thread for screws or bolts.

When you use threaded inserts, your fasteners can get a secure grip, reducing the risk of wear or stripping over time. This improves the overall integrity of the joint, especially in areas that experience frequent stress or movement.

In robotics, where precision and durability are key, threaded inserts help to maintain the stability and reliability of the assembled components, ensuring that they perform well for a long time.

3. Locking Fasteners for Vibration Resistance

Locking fasteners are designed to resist vibrations, which makes them essential in high-tech robotics where movement and stability are important. These fasteners have special mechanisms, such as nylon inserts or unique thread designs, that prevent them from loosening over time.

In robotics, where the components often experience constant motion or shocks, locking fasteners ensure that the parts stay firmly in place. They prevent unintentional loosening, which helps to maintain the robot’s structural integrity and reliable performance.

Whether they’re used in joints or mounting points, locking fasteners are a key component in keeping robotic systems stable and functional even under demanding conditions.

4. Rivet Nuts for Strong, Permanent Attachments

In robotics assembly, rivet nuts are ideal for creating strong, permanent attachments. These fasteners are installed by inserting them into a pre-drilled hole and then compressing them to form a secure grip.

Rivet nuts provide a strong threaded anchor in materials that might be too thin or soft for traditional screws. They’re especially useful in robotics for attaching panels, brackets, or other components where a sturdy connection is needed.

Their permanent installation ensures that parts remain firmly attached, even under stress or repeated use. As a result, the robotic system will continue to be durable and reliable.

5. Adhesive Bonding Fasteners for Smooth Surfaces

Adhesive bonding fasteners are perfect for creating smooth, seamless connections in high-tech robotics. These fasteners use strong adhesives to join components without the need for traditional mechanical fasteners like screws or bolts.

They’re especially handy for attaching parts to smooth or non-threaded surfaces where other fasteners might not be effective. They provide a clean, secure bond to help maintain the robot’s sleek design and reduce the risk of interference with delicate parts.

They’re great for applications where a flush, smooth finish is important for ensuring that the robotic assemblies are aesthetically appealing and functional.

6. Magnetic Fasteners for Modular Robotics

Magnetic fasteners are excellent for modular robotics, where easy assembly and disassembly are essential. These fasteners use strong magnets to hold parts together, allowing for quick and tool-free connections.

They’re ideal for robots with interchangeable or modular components, as they make it easy to swap parts or reconfigure designs as needed. They provide a secure hold while also allowing for easy adjustments or repairs.

This flexibility is particularly valuable in robotics where parts might need frequent updates or modifications. Overall, magnetic fasteners help smoothen the assembly process and maintain a versatile, adaptable robotic system.

To Sum Up

Fasteners may seem like small components, but they play an important role in the success of high-tech robotics assembly. From precision screws to magnetic fasteners, each type has a unique purpose, ensuring stability, durability, and adaptability in robotic systems.

By understanding these six types of fasteners and their benefits, engineers can build stronger, more efficient robots that stand up to the challenges of advanced technology. Small details make a big difference, and the right fasteners are the keys to taking robotics to the next level.

Leave a Reply