In modern industrial fields, cranes play an essential role in material handling across various industries such as ports, construction, and manufacturing. With the continuous advancement of technology, wireless remote control has become one of the key technologies to enhance crane operation efficiency, safety, and flexibility. Through remote control, operators can control cranes from a greater distance, avoiding safety hazards often associated with traditional operation methods, while significantly improving operational efficiency.

Overview of Wireless Remote Control Technology

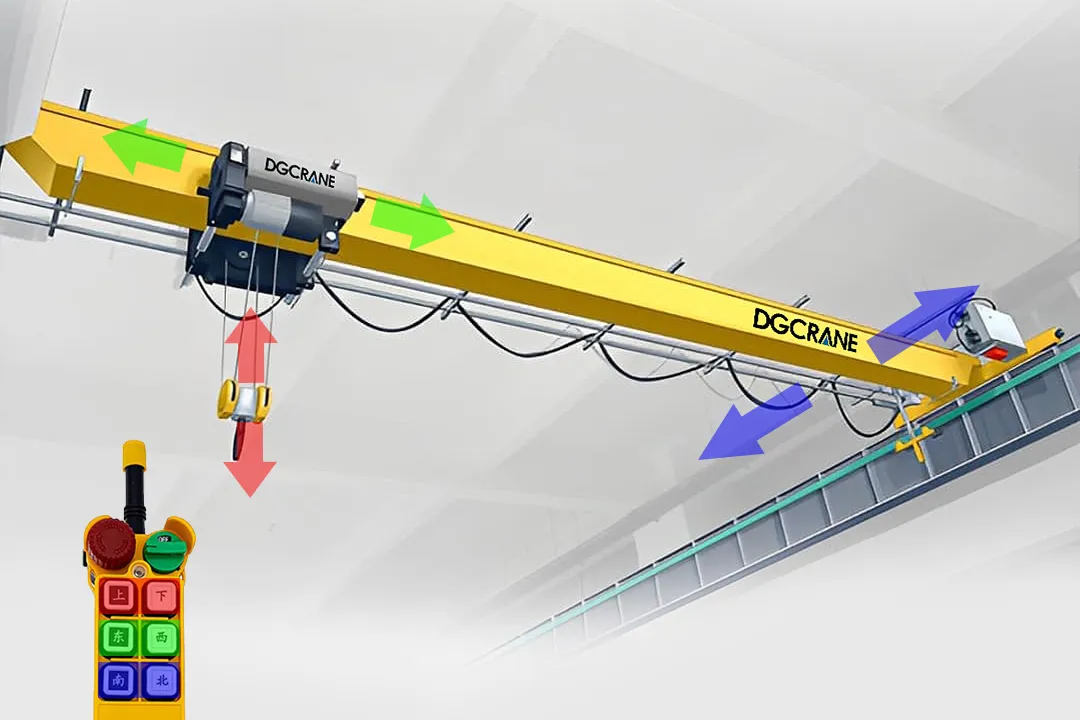

Crane wireless remote controls use wireless communication to transmit data between the crane’s control system and remote devices (such as handheld controllers, mobile terminals, etc.), allowing operators to control the crane without direct physical contact. This technology typically includes the following core components:

- Wireless Remote Devices: These include handheld controllers, tablets, or smartphones, which communicate wirelessly with the crane’s control system. Operators use these devices to send commands and control the crane’s operations.

- Receiver Module & Control System: The crane is equipped with a receiver module that receives signals from the remote device and transmits commands to the control system, which makes the necessary operational adjustments.

- Data Transmission Network: Wireless remote control relies on stable wireless networks (such as Wi-Fi, Bluetooth, or dedicated wireless frequencies) for real-time data transmission, ensuring quick response to operational commands.

- Safety Monitoring System: To ensure operational safety, modern wireless remote control systems are often integrated with real-time monitoring systems, providing feedback on the crane’s status, load conditions, and environmental data, and issuing early warnings of potential risks.

Applications of Wireless Remote Control Technology

Wireless remote control technology is widely applied in cranes, particularly in the following sectors where it provides significant advantages:

- Port Cranes: In busy port terminals, cranes handle a large volume of containers and heavy cargo. Traditional crane operation requires operators to work inside a cabin, but with a wireless remote control, operators can control the crane from various locations on the dock. This method not only improves work efficiency but also reduces operator exposure to high-risk environments.

- Construction Cranes: In construction, especially in high-rise projects, cranes often need to work in complex environments. Wireless remote control allows operators to remotely control cranes from a safe area, reducing safety risks associated with high-altitude work. Furthermore, operators can adapt to changing construction conditions and adjust operations in real-time.

- Manufacturing and Workshop Cranes: In heavy machinery production workshops or manufacturing plants, cranes often need to handle heavy and precise components. Wireless remote control enables operators to control the crane more flexibly and efficiently, ensuring safe handling of materials and increasing overall work speed.

- Mining and Heavy Industries: In hazardous environments like mines or the crane steel industry, operators must avoid exposure to harmful substances or harsh conditions. Wireless remote control technology enables operators to control cranes remotely from a safe location, significantly reducing the risks associated with direct equipment operation.

Advantages of Wireless Remote Control

- Enhanced Safety: Traditional crane operation often requires operators to work in unsafe environments, such as high altitudes, confined spaces, or exposure to harmful gases. Wireless remote control technology allows operators to control cranes from a safe area, reducing their exposure to dangerous environments.

- Flexibility and Efficiency: With wireless remote control, operators are no longer confined to a fixed cabin and can operate the crane from various positions within a wider work area. In complex environments, operators can adjust operational angles, speeds, and loads to ensure more precise and efficient operations.

- Reduced Human Error: Wireless remote control systems transmit data accurately and provide real-time feedback, reducing operators’ work pressure and minimizing the risk of human error. Modern remote devices often include fail-safe features, such as multiple confirmation steps and restricted operation modes, which help avoid unnecessary accidents.

- Improved Equipment Monitoring and Management: Wireless remote control systems are often integrated with real-time monitoring functions, allowing operators to view the crane’s load, operational status, and environmental data. This leads to smarter equipment management, as issues can be detected early, allowing for predictive maintenance and extending the equipment’s lifespan.

- Cost Efficiency: While the initial investment in wireless remote control technology may be high, it reduces reliance on traditional cabins, cutting labor costs, and improving operational efficiency. Over time, it also reduces costs related to accidents and operational errors.

Global Market Trends and Challenges

With the continued development of wireless technologies, an increasing number of crane manufacturers worldwide are incorporating wireless remote control into their designs. In developed countries like the U.S., Germany, and Japan, the application of wireless remote control technology has already reached a mature level, achieving significant results across various industries.

However, the global adoption of wireless remote control technology still faces challenges. For instance, the high initial cost of equipment, particularly for small and medium-sized enterprises, may pose a financial barrier. Additionally, there are still issues related to device reliability, wireless signal stability, and overall safety that need further optimization and resolution.

Future Outlook

In the future, with the widespread adoption of 5G technology, the response speed of wireless remote control will become even faster, and signal coverage will be more extensive, further accelerating the global application of this technology. Additionally, the integration of artificial intelligence (AI) and big data may make remote crane operations more intelligent, allowing for automatic adjustments to operational parameters and work paths, and ultimately improving both efficiency and safety.

Conclusion

Wireless remote control technology, as an innovative advancement in the crane industry, not only enhances the flexibility and safety of crane operations but also brings about a revolutionary change in industrial operations worldwide. As the technology continues to mature and its applications deepen, wireless remote control is set to become an essential trend in the crane industry, driving the shift toward more intelligent, efficient, and safe operations across various sectors.

Leave a Reply