Effective inventory management is more critical than ever in today’s fast-paced and dynamic business world. As companies strive to optimise their supply chains and meet customer demands, they must also navigate many risks that could disrupt their operations. One key component in mitigating these risks is the implementation of robust inventory control systems. In this blog, we will explore the significance of inventory control systems and how they play a pivotal role in business risk mitigation.

Understanding Inventory Control Systems

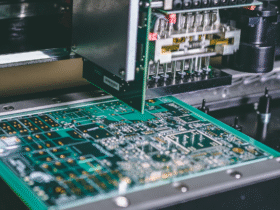

Inventory control systems are the backbone of a well-organised supply chain. These systems involve using technology and processes to oversee, manage, and optimise the storage and movement of goods within a business. The primary goal is to maintain optimal inventory levels, ensuring that products are available when needed without excessive overstock.

A comprehensive inventory control system incorporates various elements, including real-time tracking, demand forecasting, order management, and data analytics. By leveraging technology and data-driven insights, companies can better understand their inventory levels, movement patterns, and potential risks.

Read Also:- Marketing

Risk Factors in Inventory Management

Before delving into the role of inventory control systems in risk mitigation, it’s crucial to identify the key risk factors that businesses face in inventory management:

Overstocking and Understocking: Maintaining excessive inventory ties up capital and storage space, leading to increased carrying costs. On the other hand, understocking can result in stockouts, negatively impacting customer satisfaction and potentially causing revenue loss.

Supply Chain Disruptions: External factors, such as natural disasters, geopolitical events, or global pandemics, can disrupt the supply chain and affect the timely delivery of goods and services.

Obsolete Inventory: Products that become outdated pose a significant risk. Holding onto obsolete inventory ties up resources and can lead to financial losses.

Inaccurate Demand Forecasting: Poor forecasting can result in incorrect inventory levels, leading to imbalances in supply and demand.

Security Risks: Theft, pilferage, or damage to inventory during transit or storage can result in financial losses and impact a company’s reputation.

The Role of Inventory Control Systems in Risk Mitigation

1. Real-time Visibility:

Inventory control systems provide real-time visibility into stock levels, allowing businesses to monitor their inventory at all supply chain stages. This visibility enables proactive decision-making, helping to prevent stockouts or overstock situations. By staying informed about inventory movement, companies can respond swiftly to changing market conditions and customer demands.

2. Data-Driven Decision Making:

Leveraging inventory control systems using data analytics assists businesses in making informed decisions. These systems analyse historical data, market trends, and customer behaviour to generate accurate demand forecasts. This reduces the risk of understocking or overstocking and ensures that inventory levels align with actual demand.

3. Optimised Reordering:

Inventory control systems automate the reordering process based on predefined parameters. This ensures that products are replenished on time, minimising the risk of stockouts. By optimising reorder points and order quantities, businesses can balance keeping inventory costs low and meeting customer demands.

4. Supply Chain Resilience:

Inventory control systems build resilience in the face of supply chain disruptions. By identifying potential risks and diversifying suppliers, businesses can mitigate the impact of external factors. Additionally, real-time tracking enables quick response to disruptions, allowing companies to promptly reroute shipments or find alternative suppliers.

5. Obsolete Inventory Prevention:

Through continuous monitoring and analysis, inventory control systems help identify slow-moving or obsolete inventory. By promptly addressing these issues, businesses can avoid the financial burden of holding onto products that are no longer in demand. This proactive approach contributes to efficient capital allocation and reduces the risk of inventory obsolescence.

6. Enhanced Security Measures:

Inventory control systems often include security features such as RFID technology, barcode scanning, and geolocation tracking. These measures help prevent theft, pilferage, and unauthorised access to inventory. Improved security protects assets and safeguards the integrity of the supply chain, reducing the risk of financial losses.

7. Regulatory Compliance:

Businesses operating in various industries must conform to regulatory standards related to inventory management. Inventory control systems can automate compliance processes, ensuring businesses meet legal requirements and avoid penalties. This proactive approach minimises the risk of legal issues and reputational damage.

Read Also:- Online Shopping

Final Thoughts

The role of inventory control systems in risk mitigation cannot be overstated. These systems go beyond mere tracking and monitoring; they empower businesses to make informed decisions, optimise their supply chains, and navigate the complex landscape of inventory management. By leveraging real-time visibility, data-driven insights, and automation, companies can proactively address risks associated with overstocking, understocking, supply chain disruptions, obsolete inventory, and security threats.

As businesses evolve and face new challenges, investing in advanced inventory control systems becomes a strategic necessity and a competitive advantage. The ability to mitigate risks efficiently positions companies for sustained growth, improved customer satisfaction, and long-term success in the dynamic world of modern commerce.

Leave a Reply