The universe of design has gone through a critical change as of late, determined by propels in innovation. Among the most persuasive of these progressions is the ascent of 3D scanners. These gadgets have reformed how architects approach plan, prototyping, and creation, making them key designing apparatuses. By catching exact, high-goal information of actual articles, 3D scanners permit specialists to advance their work processes, improve item quality, and push the limits of development. Engineering tools are essential instruments that empower engineers to design, build, and innovate with precision and efficiency.

The Nuts and Bolts of 3D Examining Innovation

3D scanners work by catching the state of an article and changing it into a computerized model. This is accomplished through different techniques like laser triangulation, organized light, and photogrammetry. The decision of technique relies upon the application and the degree of detail required.

- Laser Triangulation: This strategy includes projecting a laser bar onto the outer layer of an item. The mirrored light is then caught by sensors, which compute the distance to each point on the item’s surface, making an exact 3D guide.

- Organized Light Examining: Organized light checking projects an example of light onto an item and catches the deformity of this example with cameras. This distortion permits the scanner to compute the profundity and surface data of the item, making a 3D model.

- Photogrammetry: Photogrammetry includes taking numerous photos of an item from various points. These pictures are then sewn together utilizing programming to make a 3D model. This strategy is especially helpful for catching huge items or conditions.

Improving the Plan Interaction

One of the main benefits of 3D scanners for engineers is the capacity to smooth out the plan interaction. Customarily, planning a part or item requires a lot of manual estimation and drafting, which could be tedious and inclined to blunders. With 3D filtering, specialists can rapidly catch exact estimations of existing items, which can then be utilized as a reason for new plans or changes.

For instance, figuring out is a typical use of 3D checking in designing. While a current part should be duplicated or improved, designers can check the part to make a nitty gritty computerized model. This model can then be investigated, changed, and upgraded utilizing PC-supported plan (computer-aided design) programming, decreasing the time and exertion expected to create a useful model.

Further developing Prototyping and Assembling

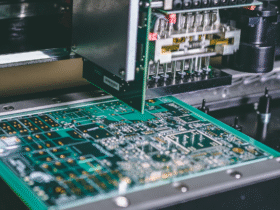

The coordination of 3D filtering into the prototyping stage has been a distinct advantage for engineers. Prototyping is a fundamental stage in the item improvement process, permitting specialists to test and refine their plans before resolving to full-scale creation. With 3D scanners, the precision and speed of prototyping have been significantly improved.

By checking a model, specialists can rapidly contrast it with the first plan details, recognizing any deviations or regions that require improvement. This cycle, known as quality control, guarantees that the eventual outcome fulfills the ideal guidelines and capabilities as planned.

Also, 3D scanners empower architects to make complex calculations that would be troublesome or difficult to accomplish utilizing conventional assembling strategies. These unpredictable plans can be handily caught and replicated with high accuracy, prompting creative items that push the limits of what is conceivable in design.

Lessening Expenses and Waste

As well as working on the plan and prototyping processes, 3D scanners likewise assist engineers with decreasing expenses and waste. By giving precise estimations and point-by-point models, 3D checking limits the requirement for different models, which can be costly and tedious to deliver. This decrease in prototyping sets aside cash as well as speeds up the general item improvement course of events.

Besides, the accuracy of 3D filtering decreases the probability of blunders during assembling. Erroneous estimations or configuration defects can prompt expensive creation postponements and material waste. By recognizing and revising these issues from the get-go in the planning cycle, designers can guarantee that the result is both savvy and harmless to the ecosystem.

Last Thought

As 3D checking innovation keeps on propelling, its effect on designing is supposed to develop considerably further. These strong designing instruments have proactively changed how specialists approach planning, prototyping, and fabricating, prompting more effective cycles, better items, and historic developments. By embracing 3D filtering, engineers are better prepared to address the difficulties of current design and push the limits of what is conceivable. Engineering tools are essential instruments that empower engineers to design, build, and innovate with precision and efficiency.

Leave a Reply