Hot rolled steel rebar, specifically HRB500 deformed steel bar, plays a vital role in modern construction. Whether building large-scale infrastructure or smaller structures, these steel bars ensure durability, strength, and flexibility. In this article, we’ll explore the benefits of using HRB500 deformed steel bars, their advantages in high-performance buildings, and how hot rolled steel rebar shapes the construction industry.

What is HRB500 Deformed Steel Bar?

HRB500 deformed steel bar is a high-tensile strength reinforcement steel used primarily in concrete construction. “HRB” stands for Hot Rolled Ribbed Bars, and “500” indicates its tensile strength of 500 megapascals (MPa). This type of steel rebar, known for its ribbed surface, provides a stronger bond between the concrete and the steel, improving overall structural integrity.

Compared to smooth steel bars, the ribbed texture of the HRB500 bar allows it to resist slipping under tension. As a result, HRB500 deformed steel bars are ideal for large-scale construction projects, such as bridges, tunnels, highways, and multi-story buildings, where strength and stability are paramount.

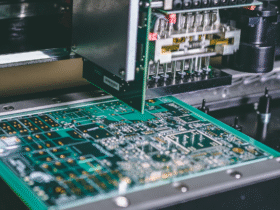

The Manufacturing Process of Hot Rolled Steel Rebar

Hot rolled steel rebar is produced by heating steel billets to extreme temperatures and rolling them into the desired shape. This process ensures the steel becomes malleable and can be formed into bars with ridges, such as the HRB500 deformed steel bar. The ribbed texture is vital because it enhances the grip between the steel and the surrounding concrete, making the overall structure more resistant to forces like tension and compression.

Hot rolled steel rebar is commonly used in projects requiring reinforced concrete because it improves the longevity and safety of the building structure. In addition, the hot rolling process ensures that the steel retains its strength and flexibility, which are essential for projects that endure extreme weather conditions or heavy loads.

Why Choose HRB500 Deformed Steel Bars for High-Performance Structures?

HRB500 deformed steel bars are specifically designed for demanding construction environments. Their enhanced tensile strength of 500 MPa allows structures to withstand higher stresses, making them ideal for high-rise buildings and infrastructure projects. Below are some benefits of using HRB500 deformed steel bars:

- Increased Tensile Strength: The 500 MPa tensile strength makes HRB500 deformed bars suitable for construction projects that require high durability and stability.

- Improved Bonding with Concrete: The ribbed texture enhances the bond between steel and concrete, ensuring the building remains stable under stress.

- Corrosion Resistance: HRB500 deformed bars are often treated to withstand corrosion, which helps extend the life of the structure.

- Cost-Effective: Despite their high strength and performance, these steel bars are cost-effective, offering a strong return on investment for large-scale projects.

Applications of HRB500 Deformed Steel Bar in Construction

Hot rolled steel rebar, specifically the HRB500 deformed steel bar, is commonly used in:

- Bridges and Tunnels: These bars provide the tensile strength necessary to withstand heavy loads and traffic vibrations.

- High-Rise Buildings: The structural integrity of tall buildings relies on steel bars like HRB500 to resist both vertical and lateral forces.

- Commercial Complexes: Reinforced concrete structures in commercial projects benefit from the added strength and durability of HRB500 deformed bars.

- Infrastructure Projects: Roads, highways, and dams use hot rolled steel rebar to maintain stability under constant stress and weight.

How HRB500 Deformed Steel Bar is Revolutionizing Construction

The use of HRB500 deformed steel bars is transforming how modern buildings are constructed. These bars provide better stability, more efficient construction techniques, and longer-lasting structures. With the ability to withstand extreme forces, such as earthquakes and strong winds, they are integral to creating safer, more resilient buildings.

In addition, HRB500 deformed steel bars are being incorporated into sustainable construction methods, making them a vital component of eco-friendly building solutions. Because they improve the efficiency of concrete use, these steel bars help reduce the carbon footprint of construction projects.

FAQs

1. What is the difference between hot rolled steel rebar and HRB500 deformed steel bar?

Hot rolled steel rebar is a general term for steel bars produced through the hot rolling process. HRB500 deformed steel bar is a specific type of hot rolled steel rebar with a tensile strength of 500 MPa and ribbed texture for better bonding with concrete.

2. Why is the HRB500 deformed steel bar important in construction?

HRB500 deformed steel bars are crucial for providing the strength and durability needed in large-scale construction projects. Their ribbed texture enhances bonding with concrete, ensuring stability and resistance to heavy loads.

3. How does the hot rolling process improve the quality of HRB500 deformed steel bars?

The hot rolling process involves heating the steel to high temperatures, which makes it easier to form into the ribbed shape. This process improves the flexibility and strength of the steel, which are essential for reinforced concrete structures.

4. Can HRB500 deformed steel bars be used in residential construction?

Yes, HRB500 deformed steel bars can be used in residential construction, especially for projects requiring extra strength, such as multi-story houses or structures in areas prone to earthquakes.

5. How do HRB500 deformed steel bars contribute to sustainable construction?

HRB500 deformed steel bars contribute to sustainable construction by improving the efficiency of concrete use, reducing the need for additional reinforcement materials, and extending the lifespan of the structure.

Conclusion

Hot rolled steel rebar, particularly the HRB500 deformed steel bar, is a game-changer in the construction industry. Its high tensile strength, excellent bonding with concrete, and corrosion resistance make it a preferred choice for large-scale infrastructure projects and high-performance building structures. Whether constructing bridges, tunnels, or skyscrapers, HRB500 deformed steel bars provide the stability and strength necessary for long-lasting and durable structures.

As construction trends continue to focus on safety, sustainability, and innovation, HRB500 deformed steel bars will remain essential to creating reliable and resilient structures that stand the test of time.

Leave a Reply