Are you tired of traditional leather tanning methods that are time-consuming and harmful to the environment? Well, get ready to discover a whole new world of revolutionary tips that will transform the way you approach the leather tanning process.

From eco-friendly alternative tanning agents to cutting-edge machinery and novel techniques, there are exciting advancements that promise faster results and improved leather quality. But that’s not all – well also explore sustainable and ethical sourcing of raw materials, as well as the latest research in leather preservation.

Eco-Friendly Alternative Tanning Agents

When seeking a more environmentally conscious approach to leather tanning, consider using eco-friendly alternative tanning agents. These agents are made from biodegradable compounds and natural extracts, making them a sustainable choice for the leather industry.

Biodegradable compounds are substances that can break down naturally without causing harm to the environment. By using these compounds as tanning agents, you can minimize the negative impact of leather production on ecosystems. They offer a safer and greener alternative to traditional chemicals, which often contain harmful toxins.

Natural extracts, on the other hand, are derived from plants and fruits. They provide a more sustainable option for tanning leather by harnessing the power of nature. These extracts not only provide excellent tanning properties but also offer added benefits such as antibacterial and antifungal properties.

Advanced Machinery for Faster Results

To expedite the leather tanning process and achieve faster results, utilizing advanced machinery is crucial. Advanced machinery offers improved efficiency and automation in the tanning process, enabling leather manufacturers to save time and increase productivity.

Here are four key benefits of using advanced machinery for leather tanning:

- Increased Speed: Advanced machinery is designed to perform tasks at a faster rate, reducing the overall production time. This allows leather manufacturers to meet tight deadlines and deliver products to customers more quickly.

- Enhanced Precision: Advanced machinery incorporates cutting-edge technology, ensuring precise control over various tanning processes. This level of accuracy helps to achieve consistent and high-quality results, improving the overall efficiency of the tanning process.

- Reduced Labor Requirements: By automating certain tasks, advanced machinery minimizes the need for manual labor. This not only reduces costs but also eliminates the risk of human errors, resulting in improved efficiency and a more streamlined production process.

- Improved Safety: Advanced machinery is equipped with safety features that protect workers from potential hazards in the tanning process. These safety measures help create a safer working environment, reducing the risk of accidents and injuries.

Incorporating advanced machinery into the leather tanning process can significantly enhance efficiency and productivity. By leveraging the benefits of automation and precision, manufacturers can achieve faster results without compromising on quality.

Novel Techniques for Improved Leather Quality

One effective way to achieve improved leather quality is by implementing innovative techniques. By using enhanced dyes for vibrant leather colors, tanners can create products that are visually appealing and in high demand. These enhanced dyes have been specifically engineered to provide a wider range of vibrant colors, allowing for more creativity and customization in leather products.

In addition to enhanced dyes, there are also innovative methods for reducing leather waste that can contribute to improved leather quality. Waste reduction is an important aspect of sustainable leather production, and new techniques have been developed to minimize the amount of leather that’s discarded during the tanning process. These methods can include more precise cutting and pattern-making techniques, as well as the utilization of advanced machinery that allows for more efficient use of raw materials.

Implementing these novel techniques for improved leather quality not only benefits the tanner but also the end consumer. By using enhanced dyes, tanners can create leather products that are visually stunning and unique. Additionally, by reducing leather waste, tanners can contribute to a more sustainable and environmentally friendly industry.

Sustainable and Ethical Sourcing of Raw Materials

How can leather tanners ensure the sustainable and ethical sourcing of raw materials?

To ensure the sustainable and ethical sourcing of raw materials for leather production, tanners should consider the following:

- Adopt fair trade practices in leather sourcing: Tanners should prioritize working with suppliers who adhere to fair trade principles. This includes ensuring fair wages and safe working conditions for the farmers and workers involved in the production of raw materials.

- Minimize the environmental impact of leather production: Tanners should actively seek out suppliers who employ sustainable farming practices. This includes using organic and natural fertilizers, minimizing water usage, and reducing chemical inputs. Additionally, tanners should encourage the use of alternative and renewable energy sources in the production process.

- Promote animal welfare: Tanners should source raw materials from suppliers who prioritize animal welfare. This includes ensuring that animals are treated humanely and that their living conditions are appropriate and ethical.

- Support local communities: Tanners should actively support and engage with local communities where raw materials are sourced. This can be done through partnerships, providing education and training opportunities, and contributing to local development projects.

Cutting-Edge Research in Leather Preservation

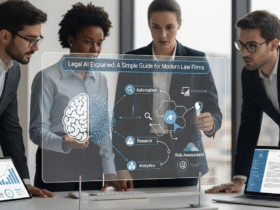

As we explore the realm of cutting-edge research in leather preservation, tanners must stay informed about the latest advancements in order to enhance the longevity and quality of their leather products.

In recent years, artificial intelligence (AI) advancements and nanotechnology applications have revolutionized the field of leather preservation.

Artificial intelligence has brought about significant improvements in leather preservation processes. AI algorithms can analyze vast amounts of data and identify patterns that humans may overlook. This enables tanners to optimize their preservation techniques and minimize any potential damage to the leather. For example, AI can predict the ideal temperature, humidity, and chemical composition required to preserve different types of leather, resulting in superior quality products.

Nanotechnology, on the other hand, has introduced groundbreaking methods for enhancing the durability and resistance of leather. Nanoparticles can be incorporated into the leather’s structure, creating a protective barrier against moisture, stains, and UV radiation. This not only extends the lifespan of the leather but also improves its overall appearance.

Nanotechnology also offers the potential for self-healing leather, where microscopic capsules containing repair agents are embedded in the material. When the leather experiences damage, these capsules release the repair agents, restoring the leather to its original state.

Read Also:- AI and Beyond

Leave a Reply