Air compressors are essential tools in various industries, offering a versatile solution for powering pneumatic tools and machinery. How does an air compressor work? Understanding this aspect is fundamental to maximizing its efficiency and longevity. Let’s delve into the intricacies of air compressors, focusing on the working principle and operational mechanisms.

Compression Process

The core function of an air compressor revolves around the compression of air. It begins with the intake of atmospheric air, which is then compressed to a higher pressure level. This compressed air is stored in a tank, ready for utilization in various applications.

Types of Air Compressors

Air compressors come in different types, including reciprocating, rotary screw, and centrifugal compressors. Each type operates on varying principles but serves the common purpose of compressing air for diverse industrial tasks.

Read Also:- Myenvoyair

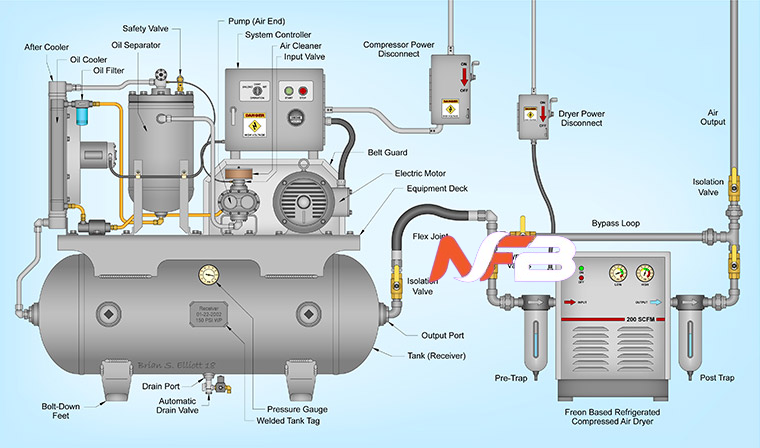

Components of an Air Compressor

An air compressor comprises several key components, each playing a crucial role in its functionality. These components include the motor or engine, pump, tank, and pressure switch. The motor or engine provides the necessary power to drive the compression process, while the pump facilitates air compression and storage within the tank. The pressure switch regulates the compressor’s operation based on preset pressure levels.

Step-by-Step Guide: How Does an Air Compressor Work?

- Air Intake: The compressor draws in atmospheric air through a filter, removing impurities and contaminants.

- Compression: The intake air is compressed to a higher pressure level by the pump, significantly increasing its density.

- Storage: The compressed air is stored in a tank, maintaining its high-pressure state until required for use.

- Release: When needed, the compressed air is released from the tank through an outlet, powering pneumatic tools or machinery.

Applications of Air Compressors

Air compressors find extensive applications across industries, including automotive, construction, manufacturing, and healthcare. They power a wide range of pneumatic tools such as drills, nail guns, impact wrenches, and spray guns, facilitating efficient and precise operations.

Importance of Maintenance for Air Compressors

Regular maintenance is crucial for ensuring the optimal performance and longevity of air compressors. This includes tasks such as checking and replacing air filters, monitoring oil levels, inspecting for leaks, and lubricating moving parts. Proper maintenance not only enhances efficiency but also reduces the risk of costly breakdowns.

Common Issues and Troubleshooting Tips

Despite their robustness, air compressors may encounter issues such as air leaks, pressure fluctuations, and motor malfunctions. Prompt troubleshooting is essential to address these issues effectively. Simple measures such as tightening connections, replacing faulty components, and adjusting pressure settings can often resolve common compressor problems.

Advantages of Using Kotech Air Compressors

Kotech air compressors offer numerous advantages, including high efficiency, reliability, and durability. With advanced technology and precision engineering, Kotech compressors deliver consistent performance across various industrial applications. Additionally, their user-friendly design and ease of maintenance make them a preferred choice for professionals and enthusiasts alike.

Conclusion

In conclusion, understanding the air compressor working principle is vital for maximizing their utility and efficiency. By comprehending the compression process, components, and operational mechanisms, users can harness the full potential of these versatile tools across diverse industries. With proper maintenance and troubleshooting, coupled with the advantages of Kotech air compressors, businesses and individuals can achieve optimal performance and productivity in their operations.

Read Also:- Aiotechnical.com Health & Beauty

FAQs

- Are air compressors noisy?

- While some air compressors can produce noise during operation, modern models are designed with noise reduction features to minimize disruptions in work environments.

- Can air compressors be used for inflating tires?

- Yes, air compressors are commonly used for inflating tires, offering a convenient and efficient alternative to manual pumps.

- What safety precautions should be followed when using air compressors?

- Users should always wear appropriate safety gear, such as eye protection and ear defenders, when operating air compressors. Additionally, proper ventilation and regular equipment maintenance are essential to prevent accidents and ensure safe operation.

- How often should air compressor oil be changed?

- The frequency of oil changes depends on the compressor’s usage and manufacturer’s recommendations. Typically, it is advisable to change the oil every 500 to 1000 hours of operation for optimal performance and longevity.

- Can air compressors be used in medical applications?

- Yes, air compressors play a crucial role in various medical applications, including respiratory therapy, dental procedures, and medical device sterilization, where a clean and reliable source of compressed air is required.

Leave a Reply