Among the mineral processing equipment, jaw crushers are unrivaled, being the only one that can crush and process materials with unique skills. Jaw crushers being one of the most important subsystems in different industries, like mining and construction, acquiring the knowledge of jaw crusher elements is the key factor. Let’s kick off by explaining Jaw Crushers 101, which will allow us to dispel some of the myths and give the necessary facts.

Unveiling the Powerhouses

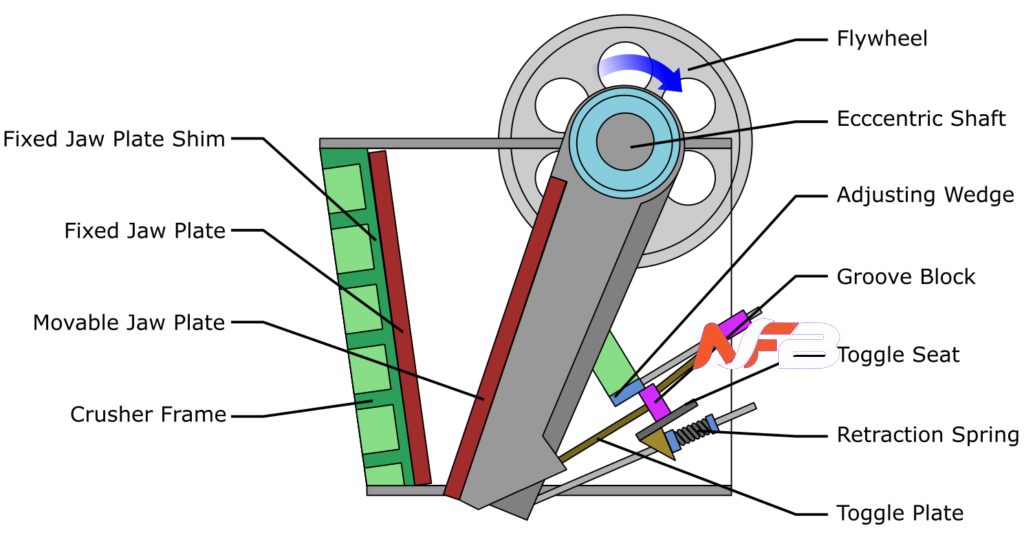

Jaw crushers are usually designated as primary crushers, they are heavy-duty machines meant to reduce large pieces of material into smaller, more manageable particles. They are indeed responsible for the reduction of the size of rocks, ores, and minerals down to a manageable size for further processing. Sometimes referred to as a jaw crusher, these types of crushers have a fixture jaw and a movable jaw that generate the incredible amount of force needed to crush materials.

Read Also:- Air Compressor Work

Dispelling 3 Myths

Myth 1: Limited Focus

Jaw crushers, unlike the common perception, are actually very unique in their versatility. Initially, these crushers were used for stone crushing and now, they have been evolved to process materials like ores, minerals, and recycled materials. Being adaptable is the key asset that makes them invaluable in multiple industries ranging from mining to recycling.

Myth 2: High Maintenance

Jaw Crushers can be depicted as having high maintenance requirements as a misconception. In essence, a modern jaw crusher is designed for high efficiency and reliability, avoiding the frequent downtime and major repair costs. With due care and regular maintenance, these pieces of equipment can work well for longer periods.

Myth 3: The Ineffective Energy Use

Another misbelief is the idea that jaw crushers are energy sucking devices. Despite the continued evolution of the architectural field, the use of energy-saving designs and technology has enabled tremendous progress in the efficiency of energy consumption. By modern crushers, we mean devices that have advanced features like the ones such as optimized crushing chambers and energy saving motors that help in reducing the energy consumption while at the same time increasing the productivity.

Advantages

1. Versatility

Ranging from first stage crushing in mines to secondary crushing in recycling plants, jaw crushers are widely used across diverse industries. Having the unique capability of handling a broad range of materials makes them highly valued machines in mineral processing plants around the globe.

2. Cost-Effectiveness

Being highly durable and rich in features, jaw crushers are still at the same time the low-cost options for the mineral processing companies. As a result of lower operating costs and much less downtime, they give fabulous value for the money, thus generating favorable return on investment for the operators.

3. Sustainability

Recent jaw crushers pay more attention to environmental protection, they have features like energy-saving motors and recyclable materials in their construction. For mineral processing equipment manufacturers, it is a matter of environment protection and resource conservation. This is achieved by designing equipment with minimal environmental impact and optimizing resource utilization.

In brief, jaw crushers manufacturers represent an apex of cutting-edge technology and productivity in the mineral processing equipment. Through the debunking of myths and the incorporation of facts, operators will unleash the true power of these powerhouses which will in turn be translated to better results in their processing operations. Without a question, whether in mining, construction, or recycling, jaw crushers become invaluable tools, which are a foundation of the mineral processing industry.

Read Also:- CNC Shearing Machine

Leave a Reply