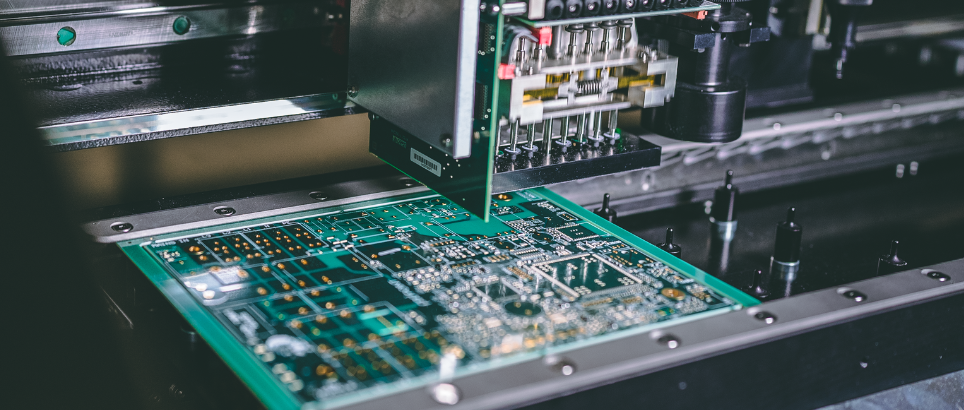

As electronic devices continue to evolve toward smaller sizes and higher performance, traditional printed circuit boards are often no longer enough to meet design demands. Engineers now require circuit boards that can fit into tight spaces, withstand mechanical stress, and maintain excellent electrical performance. This is where rigid flex pcb manufacturing and FastTurn PCB services become essential in modern electronics production.

Rigid flex PCBs combine the durability of rigid boards with the adaptability of flexible circuits in a single structure. When supported by FastTurn PCB manufacturing, businesses can rapidly prototype and produce complex boards without long delays. This combination is especially valuable in industries such as medical devices, aerospace, automotive electronics, and consumer technology.

What is Rigid Flex PCB Manufacturing?

Rigid flex PCB manufacturing is the process of producing circuit boards that integrate both rigid and flexible substrates. These boards are constructed using multiple layers of flexible polyimide films bonded to rigid FR-4 sections. The flexible parts allow the board to bend and fold, while the rigid sections provide stable mounting areas for components.

Unlike traditional PCB assemblies that use connectors and wires to join separate boards, rigid flex PCBs eliminate these extra connections. This results in a more compact, lightweight, and reliable circuit solution.

However, manufacturing such boards is a complex process that requires specialized knowledge, advanced equipment, and strict quality control.

Key Steps in Rigid Flex PCB Manufacturing

Rigid flex PCB manufacturing involves several precise steps to ensure durability and performance.

Material Selection

The flexible layers are typically made from polyimide material, known for its heat resistance and flexibility. The rigid sections are made from FR-4 or similar substrates that provide strength and stability.

Layer Lamination

Multiple flexible and rigid layers are laminated together under controlled heat and pressure. Proper alignment during this process is critical to ensure electrical connectivity and mechanical strength.

Drilling and Plating

Microvias and through-holes are drilled with high precision, followed by copper plating to create electrical pathways between layers.

Circuit Patterning

Advanced imaging techniques are used to etch circuit patterns onto both rigid and flexible layers without damaging the materials.

Testing and Inspection

Electrical testing, impedance control, and stress testing are performed to ensure the board meets performance standards.

Benefits of Rigid Flex PCB Manufacturing

Rigid flex PCBs offer several advantages over traditional rigid boards.

Space Optimization

The ability to bend and fold the board allows it to fit into compact or irregularly shaped enclosures.

Increased Reliability

With fewer connectors and solder joints, the risk of failure is greatly reduced.

Lightweight Design

Eliminating cables and connectors reduces the overall weight of the device.

Improved Electrical Performance

Shorter signal paths and fewer interconnections improve signal integrity and reduce interference.

These benefits make rigid flex PCBs ideal for advanced applications.

What is FastTurn PCB?

While advanced PCB design is important, speed is equally critical in today’s competitive market. FastTurn PCB refers to rapid PCB prototyping and production services that deliver boards within a short timeframe, often in just a few days.

FastTurn PCB services are particularly useful during product development, where engineers need quick access to prototypes for testing and refinement.

Advantages of FastTurn PCB Services

Rapid Prototyping

Designers can quickly move from concept to physical testing, allowing faster problem detection and resolution.

Shorter Development Cycles

Faster production means less waiting time and quicker project completion.

Faster Time to Market

Companies can launch products sooner by reducing delays in PCB fabrication.

Reliable Quality

Despite the fast turnaround, professional FastTurn PCB providers maintain high quality standards.

Combining Rigid Flex PCB Manufacturing with FastTurn PCB

The real advantage comes when rigid flex PCB manufacturing is supported by FastTurn PCB services. Complex boards that would traditionally take weeks to produce can now be delivered in days. This allows engineers to test, adjust, and finalize designs much faster.

For example, a medical device company designing a wearable monitor can create a compact rigid flex PCB and receive a prototype quickly. This speeds up testing, ensures proper fit, and reduces the risk of design errors before mass production.

Industries That Benefit the Most

Several industries rely heavily on rigid flex PCB manufacturing and FastTurn PCB services.

- Medical Industry: Compact and reliable boards for critical equipment

- Aerospace and Defense: Durable boards that withstand harsh environments

- Consumer Electronics: Slim designs for modern gadgets

- Automotive Sector: High-performance control systems and sensors

- Industrial Automation: Flexible boards for complex machinery

Choosing the Right Manufacturer

When selecting a manufacturer, it is important to consider:

- Experience in rigid flex PCB manufacturing

- Advanced equipment for precision production

- Ability to offer FastTurn PCB services

- Strong quality assurance and testing processes

- Technical support for design optimization

A manufacturer with both capabilities ensures high performance and timely delivery.

Conclusion

The demand for compact, durable, and high-performance electronic devices continues to grow. Rigid flex PCB manufacturing provides the design flexibility and reliability required for modern applications, while FastTurn PCB services deliver the speed necessary for rapid development and production.

Together, these technologies allow businesses to innovate efficiently, reduce development time, and bring high-quality products to market faster. Whether for medical, aerospace, automotive, or consumer electronics applications, rigid flex PCBs supported by FastTurn manufacturing represent the future of advanced circuit board solutions.

Leave a Reply