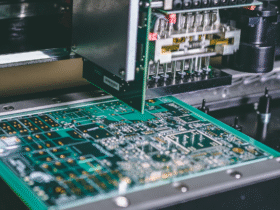

In the world of machine tools, reliability, precision, and safety are paramount. Whether it’s a CNC lathe, milling machine, or industrial press, accurate stopping and control mechanisms are critical for both performance and operator safety. This is where Stromag, a trusted name in power transmission solutions, stands out. Their electromagnetic clutches and brakes are engineered to deliver superior control, minimal downtime, and long-lasting performance. With stromag brake parts available and ready to ship worldwide, industries can ensure their operations remain uninterrupted.

Why Stromag Stands Out in the Industry

Stromag has built a strong global reputation by combining German engineering excellence with innovative technology. Their electromagnetic clutches and brakes are not just components—they are critical elements that ensure machine tools function with accuracy and safety. Each unit is designed to withstand heavy-duty industrial environments, ensuring performance even in high-load and high-speed applications. Moreover, Stromag focuses on modular designs, meaning stromag brake parts can be replaced quickly, reducing maintenance time and costs.

Electromagnetic Clutches and Brakes – How They Work

Electromagnetic clutches and brakes operate using an electric current to create a magnetic field. This magnetic field engages or disengages the friction surfaces, allowing precise control over machine motion. In a brake system, applying current releases the brake, and removing current engages it, bringing the machine to a stop. Stromag has perfected this technology for industrial applications, ensuring smooth engagement, consistent torque, and exceptional durability. This makes them ideal for machine tools that require exact positioning, repeatability, and rapid stopping capabilities.

Applications in the Machine Tool Industry

Machine tools demand accuracy at every step, from high-speed cutting to delicate finishing. Stromag’s electromagnetic brakes and clutches are designed for these exact requirements. They are commonly used in:

- CNC milling and turning machines

- Grinding and drilling machines

- Press brakes and stamping machines

- Robotic arms and automation systems

By integrating stromag brake parts, manufacturers can achieve faster cycle times, reduce wear on other machine components, and improve overall productivity. These brakes also contribute to worker safety by ensuring machines stop reliably during emergencies.

Advantages of Stromag Brake Parts

Choosing Stromag means investing in proven quality. Some key benefits include:

- High Torque Performance – Ensures machines stop and hold securely, even under heavy loads.

- Compact Design – Saves space while still delivering maximum stopping power.

- Low Maintenance Requirements – Long service life reduces downtime and operational costs.

- Quick Replacement – Modular design allows for fast installation of spare stromag brake parts.

- Versatile Compatibility – Suitable for a wide range of machine tool brands and configurations.

These advantages make Stromag a preferred choice for manufacturers who value precision, efficiency, and durability.

Global Shipping – Keeping Industries Running

One of Stromag’s biggest strengths is its global supply network. Downtime in manufacturing can lead to massive financial losses, so having critical parts available quickly is essential. Stromag ensures that both complete units and individual stromag brake parts are stocked and ready to ship worldwide. Whether you are in North America, Europe, Asia, or Africa, you can get the parts you need without long delays. This quick turnaround helps industries maintain continuous production, meet deadlines, and avoid costly downtime.

Safety and Compliance Standards

Safety is non-negotiable in the machine tool industry. Stromag’s electromagnetic brakes and clutches comply with strict international safety and performance standards. They are designed with features such as fail-safe braking, heat-resistant materials, and overload protection. This ensures not only operator safety but also extends the life of the machine. By using genuine stromag brake parts, companies maintain these safety standards and ensure that replacements perform as reliably as the original components.

Maintenance and Longevity

A key factor in achieving the best performance from Stromag brakes is regular maintenance using original parts. While Stromag brakes are built for long life, every component experiences wear over time. Using authentic stromag brake parts ensures compatibility, optimal performance, and warranty protection. Preventive maintenance, such as checking torque levels, cleaning dust build-up, and replacing worn friction plates, can greatly extend the service life of the brake system.

Conclusion: The Right Choice for Machine Tool Reliability

In today’s competitive manufacturing environment, every second counts. Stromag’s electromagnetic clutches and brakes deliver the precision, safety, and reliability needed to keep machine tools operating at their best. With genuine stromag brake parts available for fast worldwide delivery, industries can avoid unnecessary downtime and maintain peak efficiency. Whether you’re upgrading an existing system or replacing worn components, Stromag offers the perfect blend of engineering excellence and global support to keep your operations running smoothly.

Leave a Reply